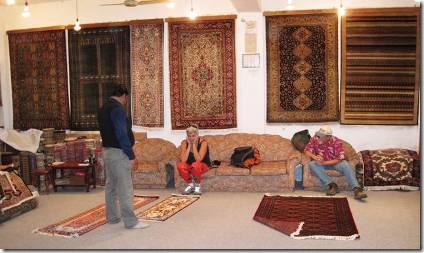

One of our stops was a carpet show room and though the rugs were very lovely and tempting, Randal is holding out for a “Turkish rug” from Turkey. Linda, Randal and I had warned Sandeep and our guide that we weren’t in the market and we warned the carpet salesman that we lived on boats, have no home to ship things to so aren’t in the market, but everyone still seemed disappointed that we didn’t buy any carpets; even the small ones. If we hadn’t been going to Turkey, we really might have been tempted!

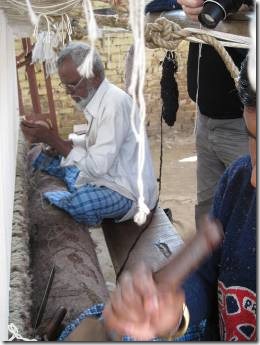

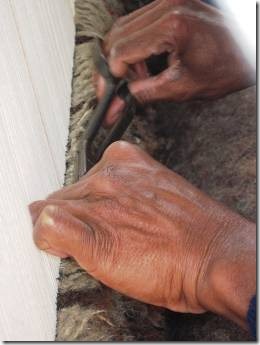

Each large hand-made carpet takes about 3 months because workers will only weave a few hours each day because of the stress on their hands. And their hands moved so fast we had to ask them to slow down so we could actually see what they were doing. There are 3 qualities of carpet, wool with 200 knots per square inch, pashmina with 400 knots per square inch, and silk with 600 knots per square inch. So the thicker and more coarse the yarns, the fewer the knots, the lower the price.

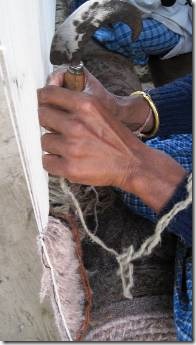

Then with a “good" scissors the threads are cut but because they are individually knotted, everything stays put and you see the pattern. (In our house we had a pair of “good scissors” that were old and black and looked something like these. My mother used them for sewing and they were wonderful scissors. One day I heard the comedienne George Carlin perform a routine about his family and the “good scissors.” On the boat we had a pair of the “good scissors” but they broke so now we need a new pair.”)

Rug weaver’s tools: this particularly company employs about 500 workers.

Linda gets an explanation about the loom which was very similar to the one we saw in Tibet and about how the pattern is established.

The carpets were beautiful.

The salesman asked Randal to pick a thread in the rug and then he pulled it out to demonstrate the difference between a hand-knotted carpet and a machine made carpet. If it’s handmade and a thread gets pulled out, only that thread will come out. If it’s machine-made the whole row will come out and be noticeable.

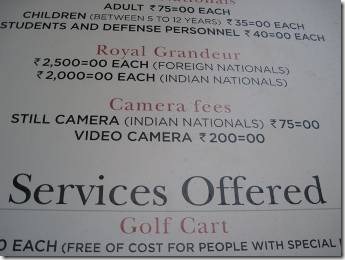

The Pink Palace which we didn’t see because of its high priced tickets.

You see these pink walls all around the city from a pink wash applied to the walls. Many city walls are mandated to remain this color if they are in certain areas.

We would have had to pay 2,500 rupees = $55 per ticket and then add another dollar or so to take photos. We just didn’t think it worth that much money though it is supposed to be beautiful. And, our guide said with a completely straight face, you are given tea or coffee inside the Palace. I asked him if anyone ever buys the tickets and he again seemed more amazed that we thought the price too high.

I noticed this woman selling puffy bread and took a photo inspired by another tourist taking a photo.

Later the other tourist told me the woman wasn’t there to sell bread, but to “sell photos” and we should have paid. My problem was that I rarely had small rupee notes. The ATMs give 500 rupee notes, so it was hard to tip everyone on earth or even give to beggars that I felt sorry for. Sandeep’s rule of giving was to give to people he thought really needed it: the very old women or people severely crippled. I once saw him give some coins to a beggar woman and asked how he decided and how much he gave to give me an idea how much to give. His answer, “I am poor so I gave only two rupees.” Well we aren’t poor and we gave nothing so what does that say? The Indian culture is certainly much more accepting of begging; it’s just hard to know who really needs it, especially after seeing Slumdog Millionaire and warnings from Lonely Planet, so I look for old women and try to give them something.

The largest silver object in the world according to the Guinness Book of World Records.

There were 2 jars and each was made from 14,000 Jaipur silver coins which had been melted into sheets of silver. A wooden mold was made and over that the sheets were beaten and shaped. No shouldering was done. The entire process took two years and both were ready by 1896. The silversmiths also shaped the lid and handles. A circular base with wheels was made for moving the jars and a ladder was made to reach the mouth when filling the jars. Maharaja Sawai Madho Singh II took both jars filled with Gangajal (Ganges water) on his voyage to England to attend the coronation of Edward VII in 1902.

Dimensions:

Weight 345 kg (760 lbs) Height 5’3” Circumference 14’10” Capacity 900 gallons (4091 litres)

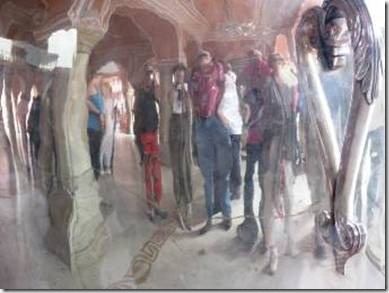

We all fit….Linda, red pants, Ruth green pants and Randal blue jeans

Aranmul Mirror

“Among Hindus in Kerala, there is a great reverence attributed to eight objects collectively known as Ashta Mangalyam (eight auspicious objects.) …..While the actual objects differ by occasion, community and location, a regular on the list is a Vaal Kannadi (hand mirror) which is meant to bestow abundance and wealth on the beholder. And the most sought after is a distortion-free Aranmula one.

The uniqueness of the Aranmula mirror is that the reflective surface is not mercury-backed glass but metal. When you place a fingertip on a normal mirror, you see a gap between the front edge of the glass and the image on the reflective backing layer. However, in the Aranmula mirror, the gap does not exist.

The secret of achieving true reflective quality on metal is known only to a set of families in Aranmula, Kerala and this knowledge was inherited as a legacy from their bronze-caster forefathers who moved to Kerala in the 18th century from present day Tamil Nadu. Legend has it that they were required to create a resplendent crown for the local deity using bell metal. But they failed to create and alloy that would, after polishing, befit the grandeur. A widow from the community dreamt about the exact composition that would make the metal as reflective as a mirror. When it proved true, the community also began to create mirrors.

Each mirror is painstakingly made by hand and, depending on the size, could take about six months to make. The clay used for casting, the higher concentration of tin in the copper-tin alloy and the duration of heating the alloy are but some of the aspects in a process where purification of the metal is of great importance to get a good shine. Even polishing the metal is said to be an elaborate process, done for a few hours each day for about three days.

A round mirror of 5” diameter set in an ornate brass frame costs about 8,000 rupees (about $175 US.) A major component of the cost is labor. But the other factor is considerable wastage in the manufacturing process as the metal plates are almost glass-like in their fragility. Traditionally the demand for the product grew when it was included in the Ashta Managalyam. However, owing to the price, it is now considered a precious and unique artifact.

Aranmula mirrors have now been granted GI (Geographical Indication) status and they are currently manufactured by the Parthsaradhy Handicraft Centre in Aranmula (www.aranmulakannadi.com.)

Culturama February 2011 Spice Jet Airlines

Interestingly, I really didn’t realize this mirror in the Pink Palace complex was special until Linda pointed out the article about it in the airline magazine we had each helped ourselves to. I had focused on the article about the puppet master. However, it is pretty interesting and our stainless steel refrigerator front works the same was as one of the Aranmula mirrors! No space between my finger and the reflection.